AMCA 210 Airflow & Pressure Test Chamber Fan Performance Test System JX-WT1000

JX-WT1000 AMCA-210 Airflow Test Chamber with computerized control system and P-Q curve display, designed for high-precision fan performance testing.

It is a precision aerodynamic testing solution for high-performance fan

Main applications: thermal testing, airflow, air pressure, speed, impedance testing.

Item No :

JX-WT1000Testing Standards :

ANSI/AMCA 210-07Airflow Range :

2.5~1120CFMAMCA 210 Airflow & Pressure Test Chamber, Fan Performance Test System JX-WT1000

Laboratory-Grade Precision for Your Fan Performance Testing

The JX-WT1000 is a fully automated airflow and pressure test chamber engineered to meet and exceed the rigorous standards of AMCA 210 and ASHRAE 51. Designed for R&D laboratories and high-end production lines, this system delivers definitive aerodynamic data for a wide spectrum of air moving devices.

Whether you are testing miniature cooling fans running at 200,000 RPM or industrial blowers requiring 10,000 Pa static pressure, the JX-WT1000 provides the stability, repeatability, and accuracy needed to validate your products for the global market.

Test Modes:

| Model | JX-WT4 | JX-WT60 | JX-WT250 | JX-WT600 | JX-WT1000 |

|---|---|---|---|---|---|

| Standard | AMCA210-07 | AMCA210 | |||

| Airflow (CFM) | 0.02–4.0 | 1.0–95 | 2.5–330 | 2.5–619 | 2.5–1120 |

| Pressure (mmAq) | 0–200 | 0–200 | 0–200 | 0–200 | 0–200 |

| Max Test Opening (mm) | 200 × 200 mm | 250 × 250 mm | 400 × 400 mm | 400 × 400 mm | 500 × 500 mm |

| Heat Transfer Section RQ Test | - | - | Optional | - | - |

| High Static Pressure Damper | - | - | Included | - | - |

| Multi-Fan Test Module | - | - | Optional | - | - |

| PWM Signal Generator | - | - | Included | - | - |

| Shaft Power & Torque Measurement | - | - | Optional | - | - |

| Dimensions (L × W × H, mm) | 1600 × 900 × 1600 | 1820 × 1000 × 1700 | 1820 × 1100 × 1750 | 1800 × 1200 × 1895 | 2450 × 1400 × 2100 |

| Power Supply | AC220V / 50Hz, 0.75 kW | AC220V / 50Hz, 1.5 kW | AC220V / 50Hz, 2.2 kW | AC380V / 50Hz, 3 kW | AC380V / 50Hz, 4 kW |

Understand the Core Measurement Technologies and Working Principles

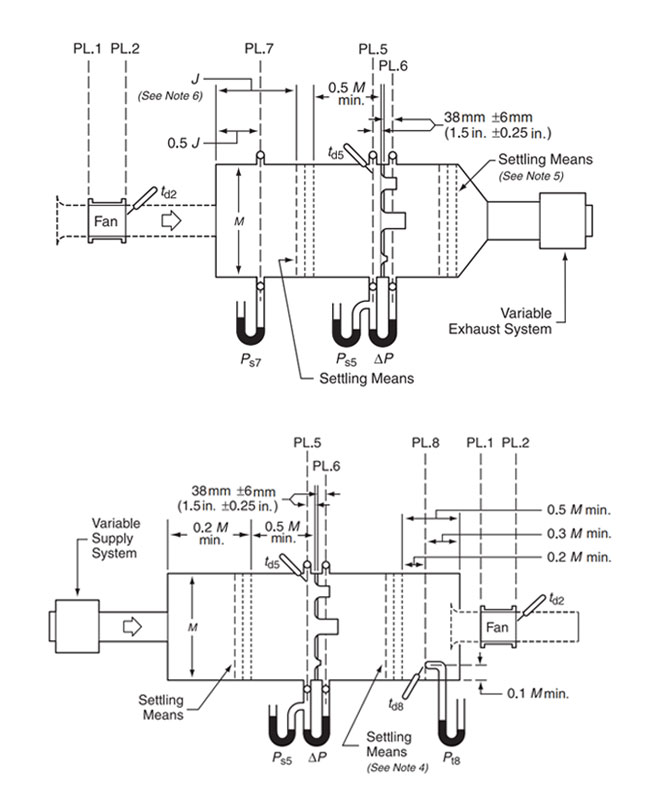

JX-WT1000 Utilizes a differential pressure chamber design with a multi-nozzle matrix for airflow measurement. The nozzles feature automatic pneumatic sealing and are equipped with upstream and downstream flow conditioners to ensure precision.

Flow Rate Calculation Formula

Flow rate of a single nozzle:

Qₙ = Cd× Uₙ × Aₙ

Total flow rate of multiple nozzles:

Q_T = ΣQₙ

Design Standards

Designed and manufactured according to the following standards:

AMCA 210-07; GB/T1236-2000; ISO5801-1997

BS848; DIN 24163; JIS B 8330-1981

Truly Present the Product's Details and Craftsmanship

Our portfolio is defined by partnerships with some of the most distinguished organizations and research bodies globally. We have successfully delivered expert solutions to a wide array of prestigious domestic and international clients, covering sectors ranging from telecommunications and electronics to motor systems and advanced materials. Our roster features tech giants like HUAWEI, AMD, OPPO, ZTE, Anker, and Goertek, alongside key manufacturing leaders such as LUXSHAREICT, CATCHER, KELLER, and China Drive Motors. Furthermore, our collaborative network extends to academic pioneers like Baibu Jiaotong University and innovators like APALTEX. This diverse track record serves as a testament to our reliability and multi-industry expertise.

Q: What types of fans can the JX-WT250 test? Does it support ultra-high-speed models?

A: The JX-WT250 is designed for exceptional versatility, covering everything from miniature to large-scale fans. It features an exclusive testing capability for ultra-high-speed fans up to 200,000 RPM, making it an ideal solution for cutting-edge industries like aerospace, servers, and medical devices.

Q: What is the maximum static pressure the JX-WT250 can handle?

A: This equipment is engineered for high-performance testing with a static pressure capability of up to 10,000 Pa. It effectively resolves the testing bottlenecks found in standard equipment, allowing for precise P-Q curve analysis of high-resistance and high-pressure fans.

Q: How does the JX-WT250 ensure measurement accuracy and airflow stability?

A: To guarantee precision, the nozzle system is equipped with professional upstream and downstream flow straighteners (flow conditioners). This design ensures a uniform and stable airflow profile, significantly reducing turbulence and meeting strict laboratory measurement standards.

Q: Is the JX-WT250 suitable for industrial-grade validation? Who uses this equipment?

A: Yes, the JX-WT250 is a trusted solution for industrial-grade validation. It has been endorsed by industry leaders and academic institutions such as Huawei, ZTE, AMD, Anker Innovations, and Xi'an Jiaotong University, proving its reliability for critical R&D and production testing.

Q: How automated is the testing process?

A: The JX-WT250 features a fully automatic control system. Operators can set parameters for automated data acquisition, curve generation, and report output, significantly improving testing efficiency and reducing human error.

Leave A Message

Scan to Wechat/Whatsapp :