Company

Founded in 2013, Guangzhou Jingxiu Thermal Equipment Co., Ltd. is a comprehensive manufacturer integrating R&D, design, production, and sales. With a registered capital of 5 million RMB and over a decade of specialized experience, we have established ourselves as a leader in the thermal and fluid testing industry.

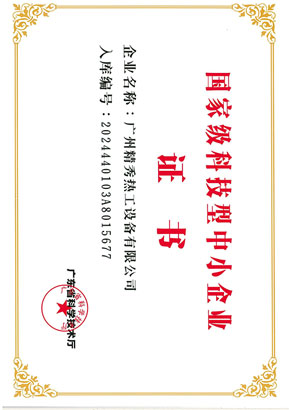

We are ISO9001 certified and hold numerous national technical patents, reflecting our commitment to innovation and quality management.

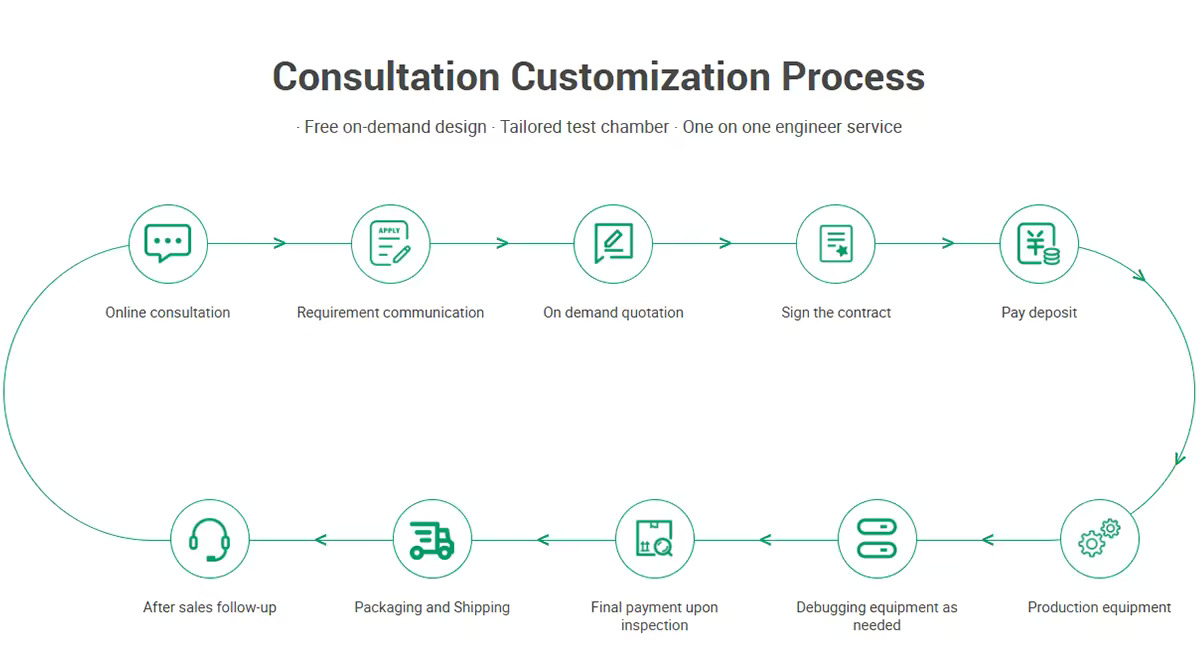

Beyond standard models, we excel in non-standard customization. We provide factory-direct pricing ensuring high cost-effectiveness without compromising on quality.

Our Mission Adhering to our philosophy of "Quality First, Service Oriented," we are dedicated to providing professional testing solutions backed by responsive support to clients worldwide.

With over 12 years of industry experience, we are your most trustworthy partner.

We are a professional manufacturer that integrates research and development, design, production, and sales.

Guided by technological innovation, continuously improving product quality and service level.

ISO9001:2015 certified high-tech enterprise, holding dozens of national patents and intellectual property certifications.

Substantial in-stock inventory ensures immediate dispatch, eliminating long waiting periods for your projects.

Deep collaborations with major manufacturers. Our successful cases testify to our quality and customer recognition.

Building a comprehensive solution for reliability quality testing laboratory

It can help developers simulate real network environments and measure product parameters such as signal strength, signal-to-noise ratio, delay, etc.

As the main members of the new energy industry, photovoltaic materials and lithium batteries generally require outdoor aging tests, battery explosion-proof tests, charge and discharge tests, etc.

Can perform ECU low-temperature testing, constant temperature testing, frost and power on testing, cold and hot cycle testing of vehicle sensor substrates, temperature characteristic testing after welding, etc.

Exterior materials such as coatings and paints can be tested for their resistance to UV radiation, salt corrosion, and changes in temperature by simulating outdoor environments.

Provide testing plans for medical equipment production, transportation, and acceptance processes, including constant temperature and humidity, low humidity, vacuum drying, and ultraviolet aging.

Mechanical environment: vibration, mechanical shock, free fall,collision, etc. Climate environment constant temperature and humidity, high and low temperature cycles, humid heat cycles, ultraviolet light, low air pressure, etc.

Leave A Message

Scan to Wechat/Whatsapp :