The three-chamber thermal shock test chamber tests the effects of rapid temperature changes on products without moving the test item. It is commonly used for electronic components, automotive parts, and high-tech products that require rigorous environmental testing and high reliability verification.

Features:

Temp Range: +70°C to +200°C (Customizable to -160°C).

Recovery Time: ≤ 5 minutes.

Design: 3-Zone Stationary Sample (Pre-heat, Pre-cool, Testing Zone).

Efficiency: Patented damper system reduces energy consumption by 30%.

Item No :

TST300W55Testing Standards :

GB/T2423.1-1989, GJB150.5-86Temperature Range :

+70°C to +200°CTemperature Fluctuation :

±2.0℃

Reliability Testing Made Precise and Efficient

The 3-Zone Thermal Shock Test Chamber is engineered to test the resistance of materials to sudden temperature changes. Unlike 2-zone elevator systems, our stationary sample design uses pneumatic dampers to switch hot and cold air instantly. This protects your delicate products (such as PCBs, sensors, and chips) from mechanical vibration during testing.

Industry Applications:

Fluiomet three-zone thermal shock test chamber is suitable for solar photovoltaic modules, batteries, automotive components, LED optoelectronics, semiconductors, aerospace, home appliances, scientific research, and other fields. It is an essential testing equipment used to test and determine the damage caused to electrical, electronic, and other products and materials by physical or chemical changes due to thermal expansion and contraction during short-term testing.

Technical Parameters

| Model | TST70W40(70L) | TST100W40(110L) | TST200W40(200L) | TST300W40(300L) | |

| Test Method | Pneumatic damper switching between 2-zone or 3-zone mode | ||||

| Performance | High Temp Room | Pre-heating Upper Limit Temp: (+200°C); Heating Rate: (+70°C → +200°C ≤ 20min) | |||

| Low Temp Room | Pre-cooling Lower Limit Temp: -75°C; Cooling Rate: (+70°C → -750°C ≤ 80min) | ||||

| Test Room | Temp Deviation: ±2.0°C; High Temp Shock Range: (+70°C → +150°C); Low Temp Shock Range: (-10°C → -55°C); Recovery Time: ≤5min*3 | ||||

| Transfer Time | Basket transfer time between High/Low temp zones ≤ 10s | ||||

| Load Capacity(Basket Steel Frame) | 30kg | ||||

| Sample Weight | 7.5kg | 7.5kg | 10kg | 10kg | |

| Internal Dim. (mm) | W x H x D | 410 x 460 x 370 | 650 x 460 x 370 | 650 x 460 x 670 | 970 x 460 x 670 |

| External Dim. (mm) | W x H x D | 1470x1850x1870 | 1710x1850x1870 | 1710x1850x1870 | 2030x1850x1870 |

| Environment | Temp: 5~35°C, Humidity: ≤85%RH, Pressure: 86~106kPa | ||||

| Materials(Shell / Inner / Insulation) | Double-sided galvanized steel (powder coated) / SUS304 Stainless steel / Rigid PU foam + Glass wool | ||||

| Chamber Construction | High Temp Room | Heater: Nickel-chromium alloy; Fan: Centrifugal & Axial flow | |||

| Low Temp Room | Heater & Cooler: Nickel-chromium alloy & finned cooler; Fan: Centrifugal | ||||

| Drive Unit | Pneumatic cylinder for basket drive; Air compressor (Optional) | ||||

| Refrigeration | Cascade mechanical compression (Water-cooled); Semi-hermetic compressor; R404A/R23 Refrigerant; Plate heat exchanger | ||||

| Controller | Display / Operation | 7" 800*400 TFT Color LCD; Constant or Program mode; Touch screen | |||

| Setting Range | Upper limit +5°C, Lower limit -5°C; Shock: High +220°C, Low -80°C | ||||

| Resolution / Control | Time: 0.1min; Temp: 0.1°C; Thermocouple input; Anti-reset windup PID + BTC | ||||

| Power Supply | AC380V ±10% 50Hz ±10% Three-phase four-wire + Ground | ||||

| Power (kW) | 23 | 25 | 36 | 36 | |

| Weight (kg) | 1100 | 1200 | 1450 | 1500 | |

| Cooling Water | Temp: ≤30°C; Pressure: 0.4~0.7MPa | ||||

| Compressed Air | 0.4~0.7MPa | ||||

| Standard Config. | Status indicator, Feed-through hole (Φ50 or Φ100), Timer, 6 Casters, 4 Leveling feet | ||||

| Safety Devices | Leakage protector, Over-temp protection, Fan/Compressor overload protection, Phase sequence protection, etc. | ||||

| Standards Compliance | 1. GB/T2423.1-1989 Low Temperature Test Method; 2. GB/T2423.2-1989 High Temperature Test Method; 3. GB/T2423.22-1989 Temperature Change Test; 4. GJB150.5-86 Thermal Shock Test; 5. GJB360.7-87 Thermal Shock Test; 6. GJB367.2-87 405 Thermal Shock Test. | ||||

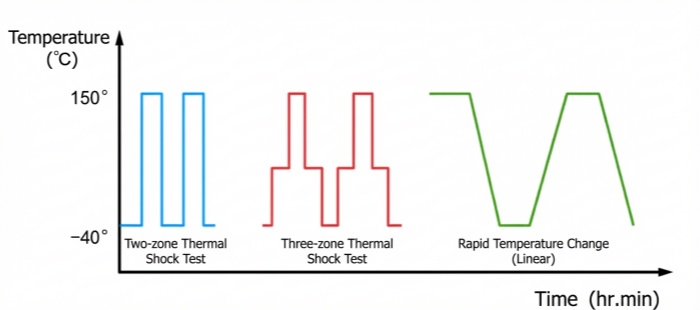

Common Temperature Cycling and Shock Test Curves:

FAQ

Q: What is the difference between 2-Zone and 3-Zone chambers?

A: 2-Zone chambers move the product (Elevator style). 3-Zone chambers keep the product stationary (Air damper style), which is safer for sensitive electronics.

Q: Can you customize the voltage for my country?

A: Yes, we support 220V/60Hz, 380V/50Hz, 415V, and 480V power standards for US, Europe, and SE Asia markets.

Q: How do you handle after-sales service internationally?

A: We provide lifetime technical support via video call. Critical spare parts are modular for easy replacement.

Leave A Message

Scan to Wechat/Whatsapp :