The high and low temperature test chamber is designed for testing the durability of products and materials under extreme temperatures, ranging from -70°C to +150°C. They are used to test the performance of components and materials in electronic and electrical products, automobiles and motorcycles, aerospace, rubber, plastics, metals, ships and weaponry, as well as in universities and research institutions, under varying high and low temperatures.

Item No :

ST1000ATesting Standards :

GB/T 5170.2-2008, GB/T 5170.5-2008Temperature Range :

-70℃~+150℃Humidity Range :

20~98%RHTemperature Fluctuation :

±0.5℃Temperature Deviation :

±3%RH (>75%RH)

The High and Low Temperature Test Chamber is designed to test the reliability, durability, and performance of materials and products under extreme thermal conditions. Whether you are testing electronics for heat resistance or automotive components for cold endurance, this chamber delivers precise temperature control and uniform airflow.

Engineered for R&D laboratories and production lines, it fully complies with international testing standards (IEC, MIL-STD, ISO).

Industry Applications:

Features

Main Structure Introduction

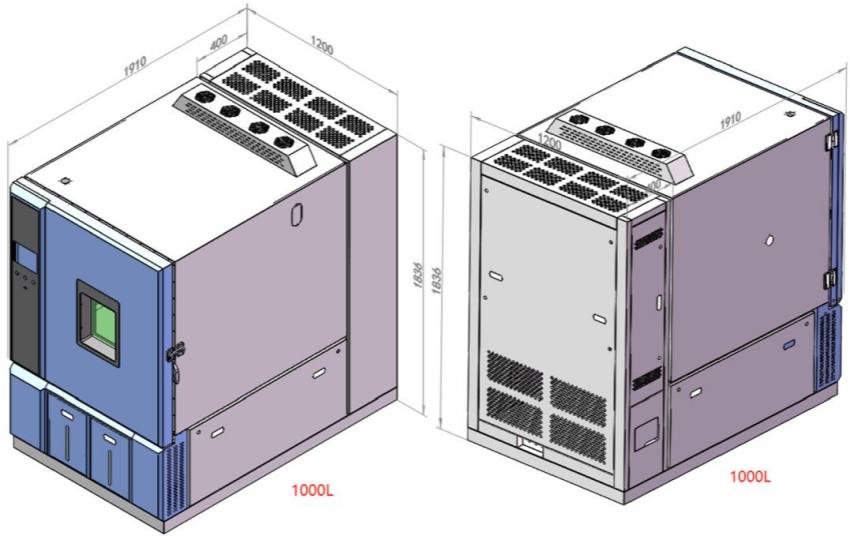

Nominal volume (liters): 80L, 150L, 300L, 500L, 1000L, non-standard customization

Temperature control method: BTHC balanced temperature control

Operating environment: Temperature (5~35℃), relative humidity (≤85%RH), atmospheric pressure (86~106KPa)

Outer shell material: Double-sided galvanized steel plate, powder-coated finish

Inner casing material: SUS304 stainless steel

Insulation material: Rigid polyurethane + fiberglass wool

Heater: Nickel-chromium alloy electric heating wire heater

Fan: Centrifugal fan

Refrigeration method: Mechanical compression binary cascade refrigeration (air-cooled)

Refrigeration compressor: Fully hermetically sealed compressor

Refrigerant: R404a/R 23

Controller

Display: 7" LCD touchscreen

Operating Mode: Setpoint and Program Mode

Setting Method: Touchscreen Setting

Program Capacity: 120 programs, 100 segments per program, 999 cycles

Setting Range: Adjustable according to the equipment's operating temperature range (upper limit +5℃, lower limit -5℃)

Display Resolution: Time (0.1min); Temperature (0.1℃); Humidity (0.1%RH)

Input: Platinum Resistance Temperature Detector

Control Method: Anti-integral saturation PID, BTC combined with temperature control

Water Supply Method: Pump supply

Water Quality: Resistivity > 500Ω*m

Power Supply: AC380V±10% 50HZ±10% Three-phase four-wire + protective ground wire

ST Series High Low Temperature Test Chamber

| Model | ST100A | ST150A | ST225A | ST408A | ST800A | ST1000A |

| Internal Volume (L) | 100L | 150L | 225L | 408L | 800L | 100L |

| Workspace Dims (mm) | 500*400*500 | 500*500*600 | 600*500*750 | 800*600*850mm | 1000*800*1000 | 1000*1000*1000 |

| Weight(kg) | 200 | 230 | 300 | 400 | 620 | 700 |

| Temperature Range | A: 0°C~150°C / B: -20°C~150°C / C: -40°C~150°C / D: -60°C~150°C / E:-70°C~150°C | |||||

| Temp Fluctuation | ±0.5°C | |||||

| Temp Uniformity | ±2.0°C | |||||

| Humidity Deviation | ±3%RH(>75%RH) | |||||

| Heating Rate | 3°C/min (Non-linear, customizable) | |||||

| Cooling Rate: | 1°C/min (Non-linear, customizable) | |||||

| Controller | Programmable Color Touch Screen Controller | |||||

| Refrigeration System | Compressor Overheating, Compressor Overcurrent, Compressor Overpressure | |||||

| Power Supply | AC 380V, 50Hz | |||||

Dimension

Leave A Message

Scan to Wechat/Whatsapp :