The natural convection temperature chamber simulates actual indoor ambient temperature, offering precise temperature control and excellent temperature uniformity. Unlike forced convection chambers, it simulates natural convection in a windless indoor environment, allowing for the understanding of a product's heat transfer characteristics under real-world use or stringent high-temperature conditions.

Main Purpose: To simulate natural convection, airflow, and temperature control in a real-world environment.

Features:

1. Airflow similar to indoor atmospheric conditions;

2. Repeatable wind field and turbulence intensity;

3. Defineable temperature uniformity;

Applications: Suitable for testing computers, mobile phones, electronic components, PSUs, D2D, networking products, LEDs, etc.

Technical Parameters

1. Temperature Range: Ambient temperature +3℃~70℃, maximum temperature rise 45℃, maximum temperature ≤70℃

2. Internal Chamber Dimensions: W860mm*D860mm*H1160mm

3. External Chamber Dimensions: W920mm*D1250mm*H1550mm

4. Quality Standard: A 9-point temperature measurement report is included with the product. The standard deviation between the measured temperature at each point and the average temperature of the 9 points is <2℃. (Specified test temperature points are 40℃, 50℃, 60℃, and 70℃)

5. Point Average Temperature: After the test chamber temperature reaches equilibrium, samples are continuously taken at each of the 9 specified temperature points for 10 minutes at a frequency of 10 seconds. This average temperature is recorded as the point average temperature for that point.

6. Set Average Temperature:

The average temperature of the 9 point average temperatures is then used as the set average temperature for that set temperature.

Main Structure Introduction

1. Test Chamber Material: 20mm thick acrylic glass;

2. Door: W834*H1179;

3. Lifting Platform: 380*230mm, effective lifting height 370mm, load capacity 250kg;

4. Heating Device: Silicon carbide heater, equipped with reflector, isolation flow equalization mesh, and insulating convection perforated plate.

5. Control Method: The chamber is divided into two zones, each with independent temperature control. Each zone has a temperature sensor, a temperature controller, and a heater, ensuring uniform temperature throughout the test chamber.

6. Lead-in Holes: Lead-in holes on both sides, 100mm in diameter;

7. Safety Protection Measures: Over-temperature protection, over-current protection, leakage protection;

8. Power Supply: AC220V/50Hz, 20A

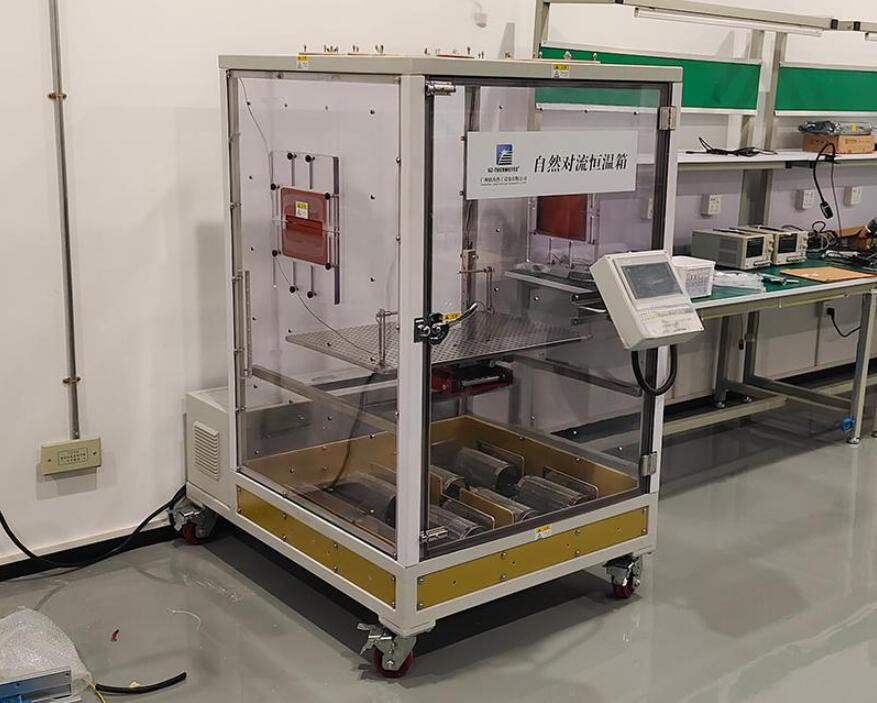

Product Showcase:

Leave A Message

Scan to Wechat/Whatsapp :